International shipping standards have evolved over the years in order to address issues related to everything from environmental waste to the control of deadly plant diseases.

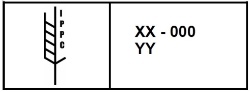

One such standard revolves around the ISPM 15 stamped or branded mark you may have seen on your wooden crates (image on right).

If the lumber used on

This article will dig into the history of the ISPM 15 heat treated wood requirements and how to be in compliance.

What is ISPM 15 heat treated wood?

The wooden crate industry has seen a number of new standards throughout the decades. This includes the International Standards for Phytosanitary Measures Guidelines for Regulating Wood Packaging Material in International Trade otherwise known as ISPM 15 heat treated wood.

The National Plant Protection Organization of the United States and the United States Department of Agriculture, in coordination with the wood packaging material industry, have developed an export program to guarantee compliance with the import requirements of trading countries. This Heat Treatment Program ensures certified treatment and marking of wood packaging material for international trade.

The Heat Treatment Program was developed in order for the American Lumber Standard Committee (ALSC) to implement a quality control program for the official labeling of heat treated wood packaging material with the ISPM 15 mark to signify compliance with the ISPM 15 heat treated wood standard.

Want helpful information on buying heat treated dunnage for your company? Check out our blog!

What is Heat Treatment?

Heat treatment is a non-chemical process to kill and prevent pests in wood.

The process ensures that all materials are treated thoroughly and not just the surface. The thermal modification of wood significantly improves its resistance to rot and fungal decay.

The purpose of this process is to assure the health of other ecosystems. When wood is imported without being treated the risk of carrying pests, such as the pinewood nematode and the Asian long-horned beetle, which can affect trees that might not have the ability to survive the disease or non-native insects. This process protects forests and other crops around the world from being infested with these pests when wood packages are delivered.

All of Valley Box's wooden crates are built with heat-treated lumber. ISPM 15 heat treated wood wood is mandatory for overseas shipments.

How to Heat Treat

Anyone with a lumber kiln and the proper measuring equipment can heat treat lumber.

However, it cannot be officially stamped as such unless it has been audited by a service accredited by the US Department of Agriculture Animal and Plant Health Inspection Service.

The wood industry chooses to use Universal’s heat treatment capabilities, a completely safe and effective method of complying