Purchasing a larger volume of crating for price quantity breaks is definitely a smart business move. However, the one drawback to buying “bulk” is the savings that will end up getting gobbled when its time to fork over additional costs for the handling and storage of all of that extra inventory.

Crating Storage Space

In general, material for crating is, well, big and bulky and it usually requires lots of floor space to store and maintain.

Think about the different types of packaging materials you might be storing right now. Do you think there might be a way to balance inventory and price?

There are many space saving solutions:

- Vendor Maintained Inventory (VMI)

- Material Handling Racks

- Collapsible Packaging

#1 Vendor Maintained Inventory

A Vendor Maintained Inventory (VMI) program operates on a minimum maximum inventory plan that is monitored by the crating company.

On hand volumes can be reduced to save storage space and crating can be replenished just in time.

This helps the customer save storage space, prevent overstocking, and the uncertainty of potential interruptions of supplies.

#2 Material Handling Racks

If you can't go under or around, go up! Stacking materials and product vertically can be a huge space saver.

If you can't go under or around, go up! Stacking materials and product vertically can be a huge space saver.

Even better a material handling rack on wheels can greatly improve space and product movement in the packaging department.

Valley Box custom manufactures material handling fixtures to accommodate a variety of loads. There are also stock racks and stacking systems available.

Take a moment to imagine your warehouse going vertical.

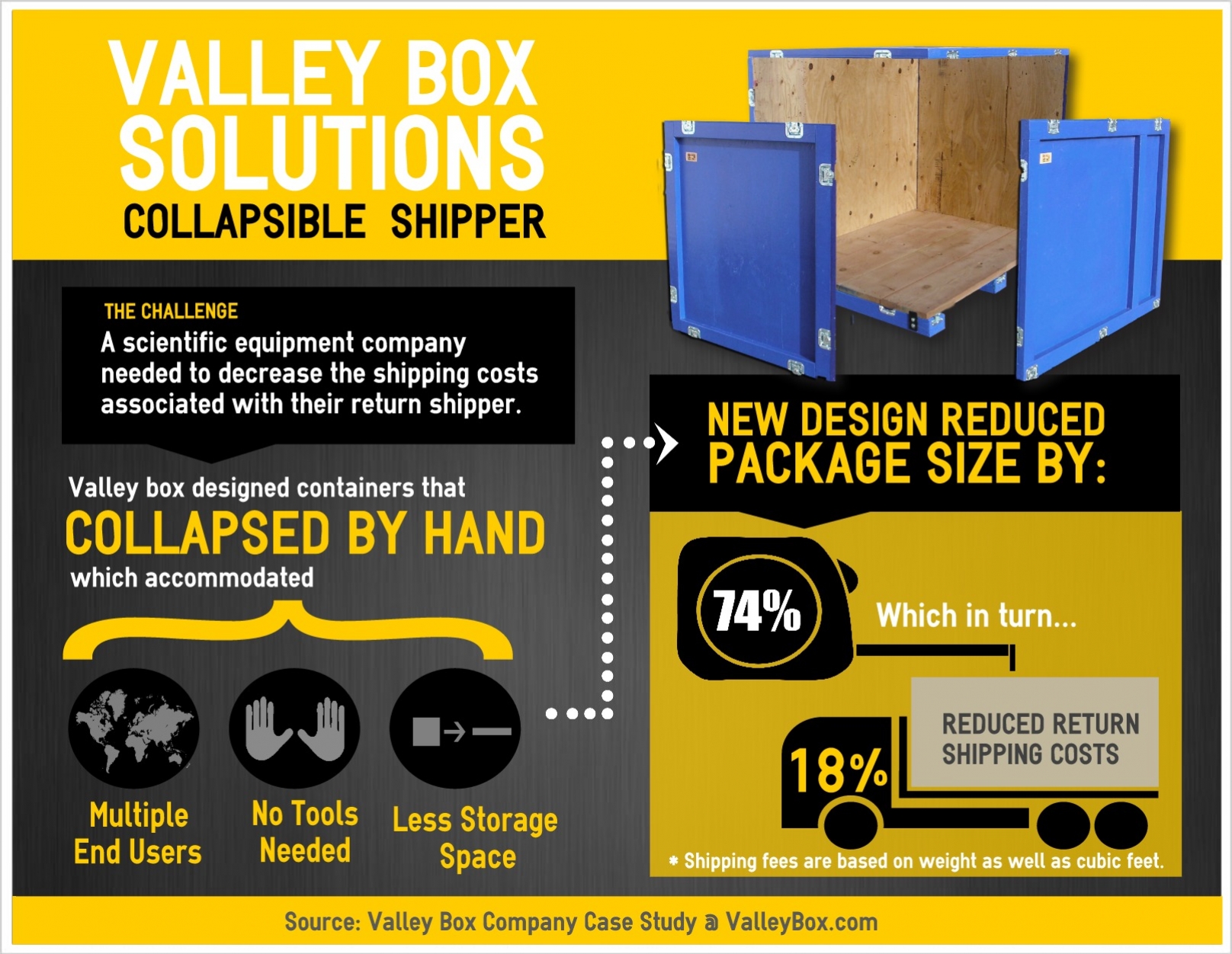

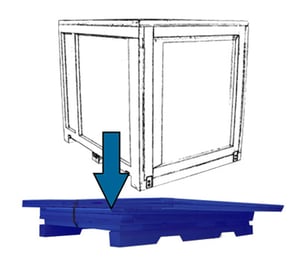

#3 Collapsible Packaging

If you have limited storage space but still need to have packaging on hand then this case study may interest you!

A Non-Profit Emergency Relief Agency required compact rapid response shipping crating for food and medical supplies. The Agency has to act quickly in order to save lives.

By having the knock down crating on-hand, responders are able to react faster and expedite the packing & shipping to get the supplies where they are needed the most.

Valley Box developed collapsible-reusable-box that

Valley Box developed collapsible-reusable-box that

- Reduced storage space by 74%

- Maintained safe & simple ease-of-use for end user

- Reduced return shipping costs when collapsed