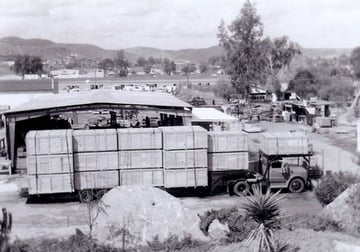

Valley Box Company is a family-owned and operated crating solutions business with its roots in the San Diego community for over 50 years!

Valley Box's combination of attentive service, durable designs and high quality standards make them a leader in the crating solutions industry.

The third generation of the family is now following the family legacy and is involved in daily operations Alicia Guillette, Robert’s daughter, has served as Valley Box's President since 2021. Alicia has taken the company into the digital age implementing a robust website and social presence, a state-of-the-art enterprise resource management tool, quality programs, and lean manufacturing practices.

The third generation of the family is now following the family legacy and is involved in daily operations Alicia Guillette, Robert’s daughter, has served as Valley Box's President since 2021. Alicia has taken the company into the digital age implementing a robust website and social presence, a state-of-the-art enterprise resource management tool, quality programs, and lean manufacturing practices.

The Legacy Continues

Valley Box has built a reputation for excellence in the industry with its commitment to three core values: attentive service, durable designs and high quality standards. These values are the foundation of their business and are the driving force behind their continued success.

Attentive Service

Valley Box's attentive service sets them apart from their competitors. They take the time to understand each client's unique needs and requirements and work closely with them to provide custom solutions that fit their exact specifications. This approach fosters strong relationships with clients and ensures that they receive the support they need every step of the way, from design to delivery.

Valley Box takes great pride in maintaining an educational gem of a blog, not only useful to educate customers about all the different aspects of Valley Box's crating capabilities but to inform the industry on best practices, workplace productivity, and quality they prove to deliver decade after decade.

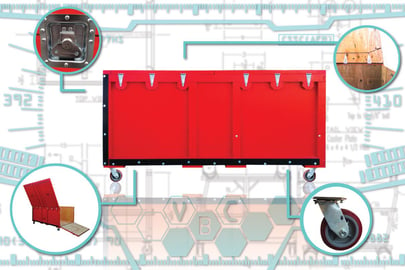

Durable Designs

Valley Box focuses on developing products that are sturdy, durable, and reliable. A strong design is one that is built to withstand the rigors of use, transport, and storage, and that can provide long-lasting performance and functionality. This can involve the use of high-quality materials, careful engineering, and attention to detail in the manufacturing process.

Valley Box's emphasis on strong designs is particularly important given the nature of the products they produce. Many of their products are designed for storage, transport, or industrial use, meaning they must be able to withstand heavy loads, repeated handling, and exposure to the elements.

By prioritizing strong designs, Valley Box can ensure that its products meet or exceed industry standards for quality and durability, providing its clients with the confidence they need to use and rely on their products for years to come.

High Quality

Valley Box's commitment to high quality is evident in every aspect of its manufacturing process. From sourcing the best materials to utilizing cutting-edge technology and skilled craftsmanship, they ensure that each product they produce meets the highest standards of quality. This commitment to excellence has earned them a reputation as a trusted partner for businesses of all sizes, across a range of industries.

San Diego

Custom Crating Solutions

Valley Box's three core values of attentive service, durable designs and high quality standards have been the foundation of its success in the manufacturing industry. Their commitment to these values sets them apart from their competitors and ensures that they continue to provide exceptional products and services to clients. With a focus on innovation, quality, and customer satisfaction, Valley Box is poised to continue its success for years to come.