Overseas customs inspections can be complicated. While there is no way around it for many manufacturers, there are ways to combat the trials and tribulations that come with shipping large quantities of equipment and other goods overseas.

You probably already know to have your packing lists, commercial invoice, original bill of lading-OB/L at its destination at least 1 week before cargo arrives. This will help to make sure everything can be processed through customs ahead of schedule.

But what about those times when a customs exam is needed for your overseas crate?

In some cases, a few tweaks to a current process may minimize potential damage and holdups at customs, while in others, a major overhaul is in order. Depending on which end of the spectrum your overseas crate falls, this could mean anything from adding a few high-tech accessories to a brand new custom design.

The case study below is just one example of how Valley Box helped a manufacturing company eliminate corrosion damage and decrease delays caused by overseas customs.

Challenge

A Packaging Equipment Manufacturer was experiencing long delays and damages caused by customs inspections of their overseas crate.

A Packaging Equipment Manufacturer was experiencing long delays and damages caused by customs inspections of their overseas crate.

In order to inspect the manufacturers' overseas crates, officials had to completely open the containers and re-seal them. This led to delays and a staggering 26% damage rate to shipments due to corrosion.

Solution

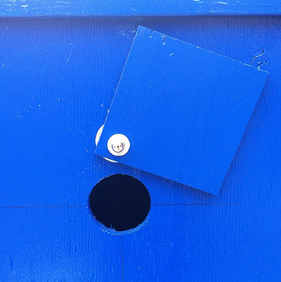

Valley Box engineers installed a plexi-glass observation window/port into the side of the container to meet customs requirements for verifying the contents of exported items.

The port also allowed a view of the moisture indicator to ensure the package continued to be properly sealed. Added weather stripping kept the port water resistant, and high-grade plexi added resistance to impact from rough handling.

Finally, a vendor surveillance program kept the company fully stocked with corrosion prevention products, which offered another layer of protection for the company’s delicate instruments.

Benefits

In addition to reducing corrosion damages to zero, the manufacturing company’s new and improved shipping container:

- Decreased inspection time

- Expedited customs inspections

- Improved on-time delivery

- Enhanced customer satisfaction

No matter what your needs may be, Valley Box has a variety of solutions to meet them. Our crating experts can enhance or create an overseas crate design that will minimize or eliminate many of the issues manufacturers must face whether they are shipping locally or overseas.

|

|