Steel is synonymous with strength, safety, and solid protection, which is why heavy-duty wood crates reinforced with steel are often the preferred choice when it comes to shipping sensitive items and equipment.

If you’re searching for a superior heavy-duty wood crate solution for your next shipment, it's best to consult a company with experience.

Valley Box's crating experts will help you decide which type of steel-reinforced crating is best for your project, but no matter which type you choose, you can count on the benefits listed below and several other advantages.

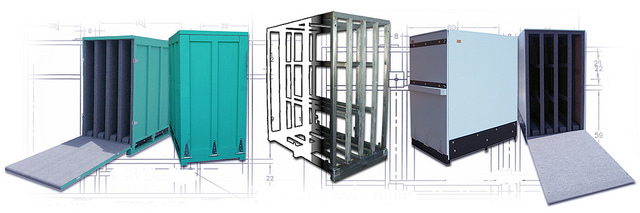

Heavy Duty Wood Crates Reinforced with Steel

- Allow for extreme length in wooden shipping crates

- Support extra wide loads

- Help support unique product shape requirements

- Reinforce hinged doors and ramps on the crate

- Can be less expensive than alternative molded shipping containers

- Can fortify the installation of accessories such as custom saddles and tie downs

Case Study: Aircraft Systems Manufacturer

For example, an aircraft systems manufacturer needed a special shipping container for two 26’ delicate wings.

Challenges...

- The length of the assembled wings exceeded the tensile allowances of the wood base, the customer had concerns about preventing damage (like bending or bowing) from rough handling.

- Additionally, the end destination had limited lifting capability. This meant that the container had to be opened and unloaded by hand.

Improved Tensile Allowance Solution

The heavy-duty wood crate experts at Valley Box created a long heavy-duty wood crate with steel reinforcement. The integrated steel in the internal structure added shear support for the unique spanned-open-lid design, tie-downs, and custom saddles were installed to support the fragile wings during transport.

Lifting Capabilities Solution

The part was accessible by a three-section lid with a drop-down end and side panels. This reduced the lid handling weight, which allowed personnel to unpack the box without the use of machines.

Steel = Protection

All of these elements—including the steel components, ensured that the wings would be well protected from beginning to end.