Believe it or not, a wooden crate can be more than just six sides, especially heavy duty crates! In fact, the geometry behind wooden container design and construction can be quite complicated.

Believe it or not, a wooden crate can be more than just six sides, especially heavy duty crates! In fact, the geometry behind wooden container design and construction can be quite complicated.

When you begin to look beyond the surface, you'll see that there is a well thought out architecture you should consider when you buy wood crates.

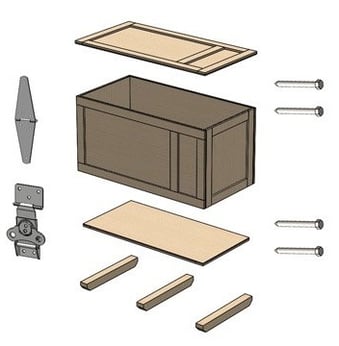

Download our "cheat sheet" for a look at the individual components

that make up strong, durable and reliable wooden crate!

Wooden Crate Design

The strength of wooden container comes from the corners, which is why a wooden crate is the strongest with 6 sides, because it produces the most corners. Evaluating wooden container design can be tricky, but once you understand the options and the benefits of each, making selections when you buy wood crates should be easier.

There are several components when you're ready to buy wood crates. Let's work from the top down:

- Lid

- Sides and Ends

- Deck

- Skid

- Hardware and Upgrades

While each component serves an individual purpose, when combined they create a shield against outside elements helping prevent damage and making handling easier.

Here is a breakdown of just some of the options that should be considered for each component when you buy wood crates.

Wooden Crate Options:

Lid

Slip Lid: Lid fits over box, with cleats to lock in place securely, aids in water shed.

Attached Lid: Facilitates side, end, or deck loading.

Loose Lid: Removable for loading from the top.

Split Lid: Split in the middle this design offers ease of lifting thanks to a two-piece design.

Sides and Ends (a.k.a. panels)

Open Crate: Allows for stacking and the lighter weight reduces freight costs.

Cleats: Increases thickness for joining surfaces with fasteners (i.e. nails, screws).

Cleats Inside: A style option that is better for shedding water.

Intermediate Cleats: Joins plywood sheets together.

Dimensional Lumber: Can be used in place of cleats or plywood.

Knockdown: Pre-built panels ready to assemble around part.

Loose Panel: Removable to allow access from side or end delivered to customer banded together.

Deck (a.k.a. base)

Loose Base: Top box lifts for easy access to heavy parts.

Attached Base: Panels are attached to base for top loading.

Light Duty: Cost effective plywood deck for light loads.

Cleated Base: Adds extra strength for light duty base.

Heavy Duty: 2x lumber deck supports the stress of heavy loads.

Super Duty: Added 4x headers strengthen base.

Headers: Dimensional lumber that runs the length or width of a deck for additional strength.

Skids

Forklift Entry: Placement of skids allows for forklift entry on one side.

4-Way Entry: Gap in skids allows forklift entry from all sides for easier loading.

Skids 4x4: Standard skid size.

Skids 4x6: Heavy-duty skids used to accommodate 2x4 cleats.

Skids (2) 2x4: Stacking 2x4's to create a 4x4 skid reduces cost.

Chamfered Skids: Notch on bottom of skid allows box to easily slide across the ground.

Hardware and Upgrades

Hardware & upgrades can transform wooden crates into reusable boxes. Upgrades can make a box more secure, weatherproof and even easier to maneuver. Check out the many types of hardware and upgrades, and the benefits you can expect to be offered when you buy wood crates.

Handles: For ease of handling smaller boxes or components of a box such as a loose side.

Hinges: Used to keep loose panels attached while being opened.

Lifting Ring: Allows loose panel or top to be lifted mechanically (i.e. forklift, crane).

Link Locks: A twist latch that allows box to be opened easily without tools.

Observation Port: A window installed in the side or end that can be used to inspect the part inside without having to dissemble the box.

Paint: Visually appealing and protects wood from UV and weather damage.

Screws: Assembly with screws offers the customer a convenient method to disassemble the box.

Lag Screw: Provides extreme strength, typically used in deck-to-skid construction.

Truck Bed Liner: Sprayed on or inside the box for abrasion prevention, durability and/or weather protection.

Of course the components of crate design are still just part of the story.

Read these helpful Valley Box articles: