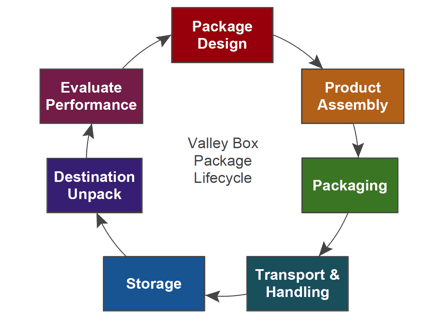

Valley Box Company, a San Diego crating manufacturer, welcomes you to this 7-part series exploring the package lifecycle with a focus on matching you with the right packaging method for your product.

You have a few options moving forward.

- Voracious Reader: Below you'll find a blog-transcript of this seventh section in the Package Lifecycle.

- Press Play: If you want to sit back, relax and let us do the talking watch the video of the presentation below!

At the end of your wood crate's lifecycle, when you evaluate the performance of the packaging, it may lead to a redesign consideration for continued improvement.

That’s why this lifecycle is a circle. With emerging technologies every year, you will always have a chance to improve upon your package design.

If you’re looking to decrease your packaging costs or improve performance, this is your stage in the lifecycle. Your San Diego crating supplier will be an advocate for cost comparisons of similar products or improving performance with a re-design.

Let's do this!

Communicate

For more effective communication, have ongoing reviews which provide a benchmark for evaluations of safety, performance, alternative packaging solutions and cost savings

Provide your San Diego crating supplier with drawings, pictures and dimensions of your product to ensure ongoing success and savings.

Tips

Some final tips about San Diego crating suppliers:

Some final tips about San Diego crating suppliers:

- Perform your due diligence by always getting at least 3 competitive quotes.

- When evaluating your packaging costs weigh factors like; Damage Costs, Packing Labor costs, and Reusablity savings.

- Communicate successful and damaged shipments for review.

- With damage claims it’s helpful to supply pictures of packaged products

- When in doubt install damage indicators to rule out mishandling.

- Evaluate the packaging company’s prices as well as their Quality, Efficiency, and level of Customer Service.

Watch more of the series

- Packaging Design - Watch the Video - Read the Blog - View the Slideshow

- Product Assembly - Watch the Video - Read the Blog - View the Slideshow

- Packaging Process - Watch the Video- Read the Blog - View the Slideshow

- Transport and Handling - Watch the Video - Read the Blog - View the Slideshow

- Storage - Watch the Video - Read the Blog - View the Slideshow

- Destination Unpack - Watch the Video - Read the Blog - View the Slideshow

- Evaluation of Performance - Watch the Video - Read the Blog - View the Slideshow