From perishables and medical devices to hazardous materials—different products require different means of protection in the world of packaging and shipping. Some products can withstand the temperatures, physical extremes, and other hazards that come with travel, shipping, and storage, while others require multiple layers of protection ranging from shock absorbing packaging materials and temperature controlled packaging to packaging with the ability to withstand corrosion, moisture and vapor, electrostatic discharge, even fungus and bacteria.

For example:

- Biotech and perishable products often require short-term temperature controlled packaging to avoid damage or spoiling.

- Electronics or machinery manufacturers use temperature controlled packaging to protect their products from potential short-term surface corrosion. Corrosion can degrade performance and longevity.

- Parts distributors require long-term protection since the storage timeline may be unknown due to unpredictable demand. Keep in mind that “storage” pertains to the time span that a package can survive and protect products from atmospheric conditions. In these cases, everything from temperature controlled packaging to waterproof containers may be employed.

Many temperature controlled packaging solutions exist, from insulated shipping containers and gel packs to cold packaging such as thermal resistant, recyclable and biostable shipping containers. The packaging you ultimately choose will depend on your own unique needs, which should always be assessed by a professional. The crating experts at Valley Box can help. First, take a look at one of our case studies. It will give you an idea of what we have to offer and you just might discover a few solutions to some of your own packaging dilemmas.

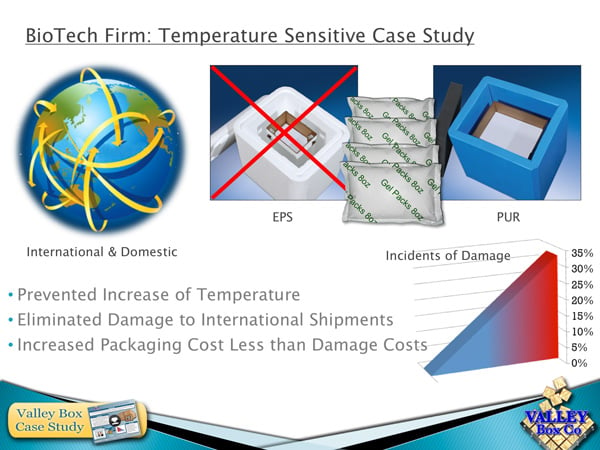

Biotech firm: Temperature Sensitive Case Study

A Small San Diego Biotech Firm ships volatile proteins for DNA testing to domestic and international destinations. These valuable and temperature sensitive proteins arrived at various international destinations damaged. The damage to the proteins was the result of a rise in temperature. Both the domestic and overseas shipments were packaged the same:

- With expanded polystyrene (EPS) containers

- With four 8 oz. coolant gel packs to maintain an ambient temperature for 72 hours

By tracking test shipments and reviewing shipping records, Valley Box found that the domestic shipments typically arrived in 48 hours in good condition, while the international shipments took twice as long to arrive. Valley Box determined that the EPS containers were not suitable for shipments that exceeded 72 hours.

Valley Box resolved the temperature issue by switching to a water-blown polyurethane foam container (know as PUR or PU), which has almost double the insulation capacity of the same size EPS container. The PUR container successfully reduced damage claims of all international shipments to zero. In the end, the benefit of eliminating damaged proteins outweighed the increased cost of the new PUR container.