When people hear the word “refurbish” the first thing that may come to mind is a refurbished product is inferior to a new one.

The truth is, that a refurbished product is often equal to its "brand-new" counterpart.

If you control your current inventory of custom wood crates you should consider reusing them. It pays to repair and maintain your investment to maximize a wooden container's value.

The Refurbished Wooden Container

First, let’s discuss what refurbished custom wood crates are and are not in the world of crating.

- Most likely the crate has been used

- May have suffered damages

- They May have succumbed to harsh weather conditions

- Most likely can be brought back to “as new” condition

- Can be re-purposed for a different use

Refurbished custom wood crates are usually elevated to the current standards of a brand-new wooden crate design. This could be the latest and greatest latch, hinge, foam, steel forklift guards, lighter-weight technology, and more.

This means the customer will still get the same protection as a new crate and the same quality to boot.

Further, a refurbished wooden container may be enhanced or customized to make it an even better fit for the customer.

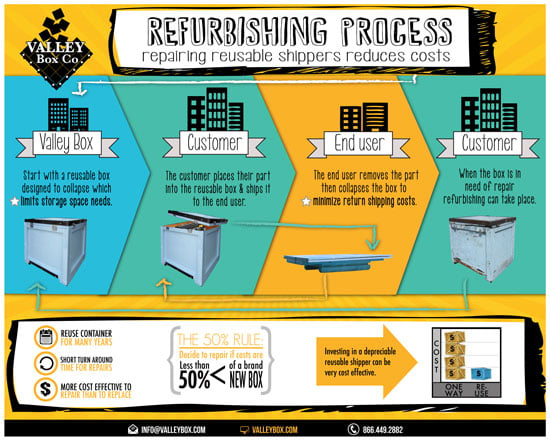

Download Valley Box's guide to the refurbishing process with before and after pictures and more details about refurbishing the process.

The 10 Year Old Wooden Container

An Engine Manufacturer wanted to know if their 10-year-old wooden crates were repairable or if they needed to be replaced. The company wanted the most cost-effective option.

An Engine Manufacturer wanted to know if their 10-year-old wooden crates were repairable or if they needed to be replaced. The company wanted the most cost-effective option.

Step 1 - Evaluate: Valley Box technicians evaluated each wooden container and noted all the materials needed to do the repairs. In the end, the repair costs were less than 50% of the price of a new crate, so the customer opted for refurbishing.

Step 2 - Repairs: Technicians removed the steel pieces on the crates, cleaned any corrosion, and repainted the steel. Wood was replaced in sections that needed it to restore structural integrity. Upgraded hardware was added in place of old technology and the interior was carpeted and re-foamed. Finally, fresh paint brought the box back to its original luster.

Step 3 - Reap the Rewards: Refurbishing the reusable crates rather than buying new ones offered the following benefits: