If you've ever been in charge of your company's booth you already know how much work trade shows can be.

From the outside looking in, it seems like it's fun to get a break from the office. You know, traveling to interesting destinations and surrounding yourself with the hustle and bustle of industry folks. But there can also be downsides, especially with the set-up (and subsequent) breakdown of your company's expensive trade show booth.

Wouldn't it be great if there was a way to solve the most common challenges at your next expo? We think so too! This is why we created the reversible trade show shipping crates!

The Drayage Fees

Challenge: Racking up drayage fees can be a real surprise. With each shipment, most trade show contractors will charge minimums on drayage. With an average rate of $78 per 100 pounds and a minimum weight per shipment of 200 pounds, that’s over $150 just to bring in one shipment!

Solution: Minimize unnecessary drayage costs by consolidating your trade show display into fewer crates. Fewer crates packed more efficiently will reduce handling charges and be more likely to weigh in above minimums. As a bonus, you can reduce freight costs because you've eliminated the weight of the unused crates.

The Installers

Challenge: There are so many details to consider when coordinating an expo for your company. Communication with the installers hired to set up the trade show booth is critical. Many exhibitors find it daunting and tedious to carefully map out the assembly and disassembly of their booths.

Solution: The Valley Box reversible crate is a great way to expedite the installer's time and reduce confusion.

The Waiting

Challenge: There are many points during the set-up and breakdown of a trade show display that exhibitors find themselves just waiting around. 1) Arrive at booth space and wait for the crate to arrive. 2) After unpacking the trade show crate wait for a forklift to take the crate to the warehouse. 3) After the conclusion of the show wait for the crate to be brought back to the booth for packing. 4) Wait for the forklift to come and take the packed trade show crate.

Solution: Cut your waiting time in half by getting with the crate! Valley Box manufactures trade show shipping crates that turn inside-out to become a part of your display. Once the crate is on the display there's no need for steps 2 and 3 above. stays in your booth as part of the display!

The Union Labor

Challenge: High price of union labor to set up your company's booth.

Solution: Higher installers or have your trade show team do it themselves! Make your display a turn-key solution so that it can be easily assembled and disassembled by a few people. Valley Box's reversible trade show shipping crates are specially designed to be transformed from a crate to display by 1 to 2 people.

The Lost Pieces

Challenge: Lost accessories such as frames, flag stands, remote controls, etc.

Solution: The fully enclosed crate keeps all the parts for your trade show in one crate.

The Theft

Challenge: Too much information or product branding on the outside of the crate can scream, "I'm valuable TAKE ME!"

Solution: The reversible trade show shipping crate has a discreet exterior so only your shipping label will offer identification of the contents.

The Lost Crate

Challenge: Hard to find a crate in a sea of other crates.

Solution: This reversible trade show shipping crate stands out with custom paint on the exterior panels, which aids in visual identification when you have to identify "which box" the guy on the forklift should be looking for on that crowded dock.

The Damages

Challenge: Commonly, trade show attendees complain about damage to their trade show items from the carriers. Your products or displays must be in pristine condition. It's a good idea to make sure that you use crates that have the protection needed for transit.

Solution: Our reversible trade show shipping crates can be made with custom-sized cubbies and shelves to securely hold fragile TV monitors, signage, and collateral. Ties down locations and ratcheted ties down secure large, heavy pieces of your trade show display, assuring a damage-free shipment.

The Missing Crate

Paint Point: External damage results in a hard identification of the package.

Paint Point: External damage results in a hard identification of the package.

Solution: Skyline Trade Show Tips suggests, "It’s also a good idea to make sure that your company’s name is clearly labeled on the inside of each box or shipping crate. These trade show crates can sometimes become damaged in transit, and it could be a disaster if the container is damaged and no one knows where the contents belong." By having the wrap on the interior panels, your box will be easily identified.

The Dropped Crate

Challenge: Trade show crates containing heavy machinery get dropped on the side and cause serious damage to the display items.

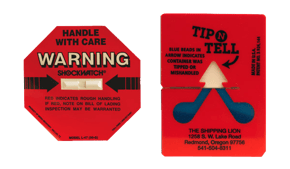

Solution: Adhere damage indicators to the outside of the container. Have trade show staff keep tip-n-tells on hand, and when one is triggered, replace it at the show before the next carrier takes the crate. This is a great way to prove when the damage occurred to trade show shipping cases.

The Stolen Stuff

Challenge: Stolen valuables, AV, and electrical equipment during the show when the booth is unattended.

Solution: Since our reversible trade show shipping crates have easy-to-remove panels, at the end of the day pop one end off and place valuables inside the crate. Out of sight, out of mind (of the thieves).