What is crate packing?

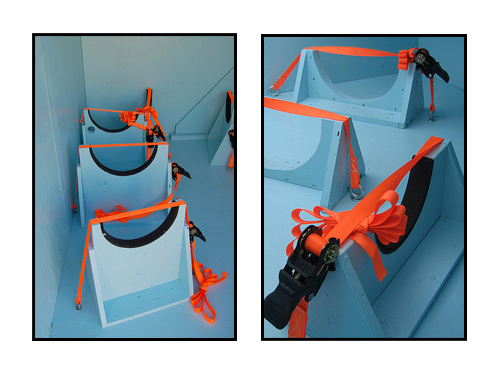

Crate packing is key for your company to protect its products inside a shipping crate. Typically parts are secured inside the crate using some form of tie-downs, saddles, foam inserts, or blocking and bracing.

By working with Valley Box you can rest easy knowing that your crate packing provider has your best interests in mind and your shipment will arrive on time and unscathed.

Blocking & Bracing

Your crating manufacturer can protect your product against damage from vibrations & impact by customizing the internal components to maximize safety when crate packing.

Blocking and bracing is a technique used to secure a part inside the packing crate, a screw or nail is placed in pieces of lumber to place around the part. This will reinforce the part's position in the crate and also helps to support the integrity of the crate from the inside out.