In the world of shipping, there are many types of shipping crate packaging materials to choose from. As you can imagine each one has its application therefore it’s important to understand the differences of each material.

Corrugated boxes

Single wall and double wall corrugated boxes are good for a manufacturer of products that are produced in large daily quantities rolling off an assembly that has a higher rate of usage and buying in large repetitive quantities.

Triple Wall

Triple wall is a triple fluted corrugated material that is lightweight and tough. Triple wall boxes are perfect for air transport or when the cost of freight is weight sensitive.

Triple wall is a triple fluted corrugated material that is lightweight and tough. Triple wall boxes are perfect for air transport or when the cost of freight is weight sensitive.

Similar-sized wood crates weigh nearly 40% more than a triple wall box.

However, since it's a fiberboard, the triple wall may not be desirable for long-term outdoor storage.

Wood Open Slat Crates

Open slat crates are lightweight, stackable, and can potentially offer a more economic outer package than its paneled wood shipping crate counterpart. They can be a cost-effective choice when determining the level of protection your product really needs.

Open slat crates are lightweight, stackable, and can potentially offer a more economic outer package than its paneled wood shipping crate counterpart. They can be a cost-effective choice when determining the level of protection your product really needs.

Light & Heavy Duty Wood Crates

Lightweight and heavy-duty wood shipping crates are perfect for the manufacturer who produces a product that is larger dimensionally or is highly customized and the package design is being addressed once the product is complete. Wooden crates are durable and customizable to the product. These styles of boxes can be built to hold payloads of any size and weight.

Lightweight and heavy-duty wood shipping crates are perfect for the manufacturer who produces a product that is larger dimensionally or is highly customized and the package design is being addressed once the product is complete. Wooden crates are durable and customizable to the product. These styles of boxes can be built to hold payloads of any size and weight.

Watch the video series

Want to learn more?

Want to learn more?

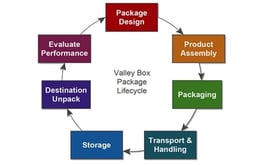

Valley Box has a video series that walks viewers through the package's life cycle.

The pre-recorded webinar starts by explaining the lifecycle and moves into the importance of planning your shipping crate design.

Watch this video to learn more!