Streamlining packaging and shipping operations without compromising your bottom line is something many manufacturing companies dream of. Fortunately, there are ways to accomplish this with a reasonable investment of time and capital. Like many manufacturing companies, your operation is likely unique, so a one-size-fits-all approach might not work. In these cases, choosing a custom wood crate option is one of the best ways to reach your intended goals.

The case study below will give you a good idea of how a custom wood crate was redesigned to address the specific needs of a manufacturer and perform a shipping function smarter.

Challenge: Long Packing Time

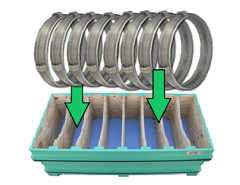

A Southern California Machining Company shipped milled rings from their Southern California plant to a sister-plant in Central California for further processing, then the rings were shipped back to Southern California for final processing before being sent to the customer. The amount of time it took employees to pack the parts cut into the company’s profit margin so significantly that they considered raising prices. This is one of the fastest ways to lose customers, so the company needed help—in a hurry.

A Southern California Machining Company shipped milled rings from their Southern California plant to a sister-plant in Central California for further processing, then the rings were shipped back to Southern California for final processing before being sent to the customer. The amount of time it took employees to pack the parts cut into the company’s profit margin so significantly that they considered raising prices. This is one of the fastest ways to lose customers, so the company needed help—in a hurry.

The first order of business was to evaluate the amount of time employees spent packing the milled rings for their sister-plant. On average, each ring required a hefty 45 minutes of pack and unpack time.

During the original packing process:

- 1. employees placed a single milled ring in a barrier bag

- 2. air evacuated

- 3. heat sealed the barrier bags

- 4. placed the bagged part in a single wood crate

The Solution: Wood Crate Redesign

Valley Box packaging experts worked with the Machining Company to discuss several key points.

- The rings were durable in the vertical and horizontal position

- The Machining Company was sending multiple rings per delivery

- The barrier bag was only necessary on the return trip

- The sister plant was discarding damaged wood crates

Valley Box engineers decided that the old design needed a major overhaul. They redesigned the container to address each of the key points with the goal of reducing packing time.

- Internal wood dividers were used to store the rings vertically rather than horizontally

- With the vertical design each wood crates utilized its internal space more efficiently and could hold more rings per delivery

- Barrier bags were applied at the sister location rather than the Southern California plant

- To make the wood crate a reusable option time and time again paint was applied inside and out to extend the life by preventing water and UV damage.

Benefits: Faster Packing Times

The new wood crate design helped decrease pack and unpack time by an impressive 90 percent. The new time? Just seven minutes. In the end, the decision to create a more customized packaging solution enhanced operations on all fronts. The Southern California Machining Company experienced:

- Improved packing times

- Decreased turn-around on part completion

- A new in-house material handling fixture

- A leaner shipping department

- Increased profits