| |

A

|

| |

B

|

|

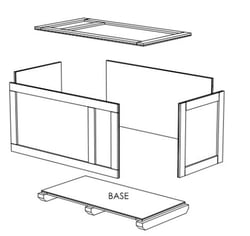

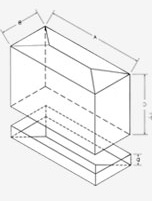

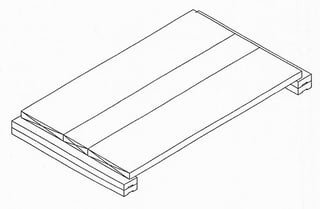

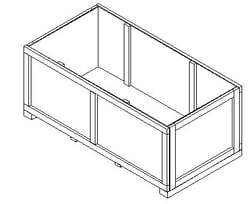

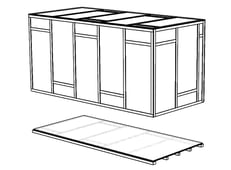

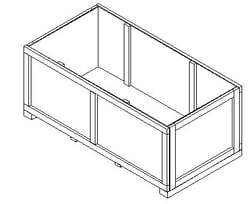

Base

The bottom panel or section of the crate or box and all its components.

|

|

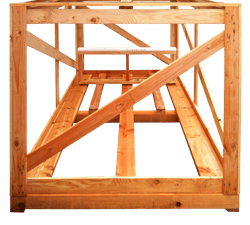

Blocking and/or Bracing

Materials & labor used primarily to prevent free movement of the packaged or unitized item. In addition, it is used to distribute the load of the contents over as much of the container surface as possible and to support the contents in such a way that the load is applied at the strongest points of the container

|

| |

C

|

|

Chamfer / Chamfered / Bevel

A flat surface made by cutting off the edge or corner of a block of wood.

|

|

|

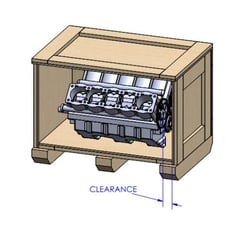

Clearance

The amount of space between two objects. When discussed in 'packaging' this refers to the part's proximity to the packaging. When discussed in 'freight' the refers to the outer dimensions (OD) of the package itself.

|

|

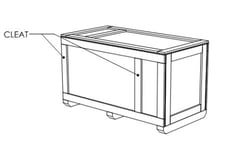

Cleats

The lumber boards which adds to the framing structure to reinforce the crate or box and adds bulk to the edges for nailing or stapling purpose.

|

|

Clinching

To secure a nail or staple by curving the pointed end that protrudes through the wooden frame member back into the wood at 90-180 degrees.

|

|

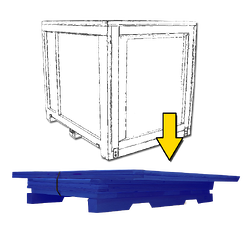

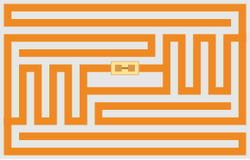

Collapsible Container

A container that is designed to come apart and be stacked on its own base therefore reducing the containers overall cubic dimensions. This can reduce freight fees for return shipments as freight is based off cubic feet as well as weight. Additionally, collapsing containers can free up shop floor space when they're not in use.

|

|

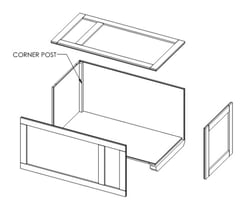

Corner Post

The vertical frame members placed between the upper and lower frame members of the side and end panels and serve as columns for supporting vertical stacking loads.

|

|

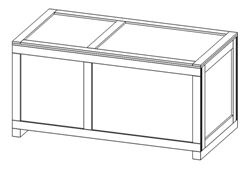

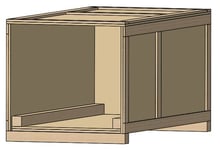

Crate / Box

A container used in the transportation and storage of items to prevent the item inside from damage caused by the outside environment.

|

|

Cushioning

Material used to mitigate the adverse effects of vibration and abrasion during the shipping, storage and handling of a package.

|

|

Customs / Examination and Inspection

If the authorities identify at the point of import that wood packaging does not carry the required mark or if the detection of pest infestation provides evidence that the treatment may not have been effective, countries may take a variety of actions, such as: Detention, Quarantine, removal of non-compliant material, treatment or repackaging at the expense of the importer, destruction, re-export, fines and/or penalties.

|

| |

D

|

|

Debarked

Based on the ISPM-15 standard, debarked wood does not have to be entirely bark free. Rather, debarked wood may have any number of visually separate and clearly distinct small pieces of bark on it, provided the pieces of bark are either:

• Less than 3 cm (1.18 inches) in width (regardless of length), or

• Greater than 3 cm in width, with the total surface area of the piece of bark less than 50 square cm (7.75 square inches).

|

|

Desiccant

A desiccant is a hygroscopic substance that induces or sustains a state of dryness (desiccation) in its local vicinity in a moderately well-sealed container.

|

|

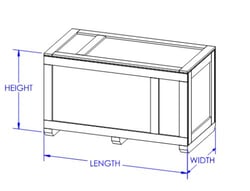

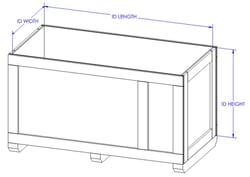

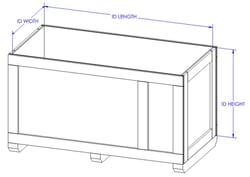

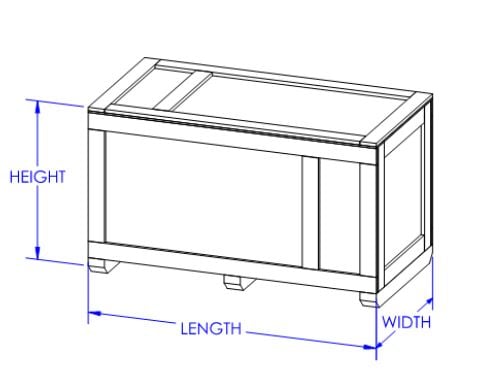

Dimensions

The distance between two points. When measured for packaging it means the horizontal and vertical distance from the inside face of each panel to its opposite panel. Always measured in Length Width and Height in that order L x W x H. Dimensions can be expressed in both outer dimensions (OD) and inner dimensions (ID).

|

|

Dunnage

Inexpensive or waste material used to load and secure cargo during transportation; more loosely, it refers to miscellaneous baggage, brought along during travel. For information regarding heat treated dunnage and valley box, click here and scroll to the second to last general FAQ:

/about-us/faqs

|

| |

E

|

|

Electro-Static discharge / ESD

Electro-Static discharges are momentary currents naturally caused by static electricity in the air.

|

| |

F

|

|

Flute / Fluted

The wavy material between the flat liner sheets in corrugated products.

|

|

Frame Members

Frame members are those parts which form the fundamental crate structure upon which the strength and rigidity of a plywood-sheathed crate depend on.

|

| |

G

|

|

Gusseted Bag

A gusseted bag is simply a pleat made into the bag, they have sides and balloon out to hold the product in a box shape. When you put something in a gusseted bag you are squaring the bottom and eliminating what are commonly referred to as dog ears -the corners of the plastic bag that would otherwise stick out.

|

|

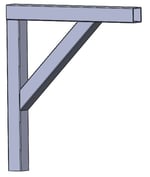

Gusset / Gusset Plate / Gusseted

Gussets are thick sheets of plywood or steel that are used to connect truss members. They add shear strength to construction.

|

| |

H

|

|

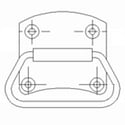

Handle

Used to lift both boxes and lids. Secured with 4 screws or lag screws.

|

|

Headers

Headers are either transverse members at each end of skid bases or longitudinal members at each end of top joists to maintain rigidity for heavy payloads.

|

|

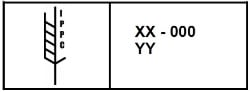

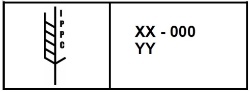

Heat Treat Stamp / HT Mark

Wood packaging materials that are ISMP-15 need to be marked to indicate that is has been treated in accordance with approved phytosanitary procedures. The mark must contain:

- The symbol - The design of the symbol (shown in the left half of the example that follows) should resemble closely the one shown in the example below and be presented to the left of the other components.

- Country code -The country code (shown in the example as XX) must be the two-letter International Organization for Standards (ISO) country code

- Producer or treatment provider code - The producer or treatment provider code (shown in the example as 000) identifies the producer of the WPM or the treatment provider who applies the mark. The codes are assigned by the National Plant Protection Organization (NPPO) of the country of WPM production or treatment.

- Treatment code - The treatment code (shown in the example as YY) is an approved abbreviation indicating either heat treatment (HT), dielectric heating (DH), methyl bromide treatment (MB). The code must appear on a separate line from the country code and producer/treatment provider code, or be separated by a hyphen if presented on the same line as the other codes.

|

|

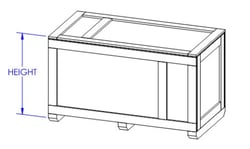

Height

The distance from the floor to the highest point of the payload.

|

|

Horizontal Cleats

Horizontal cleats are members positioned between struts and parallel to the upper and lower frame members and serve to reduce the unsupported span of the sheathing.

|

|

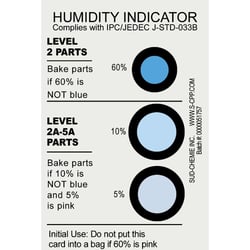

Humidity Indicator

A paper card or Plastic/Aluminum plug which indicates the percentage of relative humidity present by changing color from blue to pink as the humidity levels rises.

|

| |

I

|

|

Inside Dimension / ID

The distance from the inside of the top to inside of the bottom of the box. Commonly refereed to as ID or inside dimensions.

|

|

IPPC

The International Plant Protection Convention is an international plant health agreement that was established in 1952. As of 2013, there were 180 contracting governments that are signatories of the IPPC, all of whom share the same goal: to protect the world’s cultivated and natural plant resources from the spread and introduction of plant pests while minimizing interference with the international movement of goods and people. The IPPC provides an international framework for plant protection that includes developing International Standards for Phytosanitary Measures (ISPMs) for safeguarding plant resources.

|

|

ISPM-15

The IPPC has adopted a minimum standard for Wood Packaging Material (WPM), known as the ISPM-15 standard, which is part of this international framework. WPM made of processed wood material, referred to as man-made or engineered lumber, is exempt from compliance with the standard. The ISPM-15 standard requires that WPM be debarked, treated, and marked with the standardized, accepted stamp certifying compliance, as defined further in this section.

|

| |

J

|

|

Joist

Members extending across the crate or box underneath the top which serve to support and transfer vertical stacking loads to the side panels. Joist also serve to prevent crushing or buckling of top panels when slings or grab hooks are to lift the box.

|

| |

K

|

|

Knock Down / KD

Definition coming soon

|

| |

L

|

|

Length

Is the longest dimension of the payload that is touching the ground.

|

|

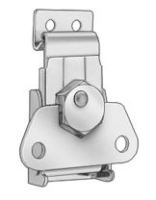

Link Lock / Butterfly latch

Turn to open draw latch.Lift the handle and turn 180° to open and close these latches. Typically this device is used to secure removable panels. This latch can be suseptable to being dislodged as they protrude from the side of the crate. (see Recessed Link Lock)

|

|

Load-Bearing Floorboards

Transverse base members which serve to distribute and transfer loads to the outside skids.

|

| |

M

|

|

Man-Made or Engineered Lumber

Wood packaging material made entirely of processed wood material, referred to as man-made or engineered lumber. Man-made wood includes plywood, oriented strand board, timber strand, and veneer that has been created using glue, heat, pressure, or a combination thereof. Man made wood is exempt from the ISPM-15 requirements.

|

| |

N

|

| |

O

|

|

OSB (Oriented Strand Board)

Engineered wood particle board formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. Good for things that do not come into contact to miosture. Because of its lack of durability, Valley box does not use this material in the onstruction of their boxes.

|

| |

P

|

|

Plywood

A sheet material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another.

Grades:

AA-Grade Face - Highest quality veneer you can specify in any particular species. The veneer will be smooth, tight cut, and full length and free of any visible defects or abnormalities.

A-Grade Face - an “A” face on hardwood plywood should be matched for both grain and color. All veneer splices should be book-matched for a visually pleasing appearance. There should not be any abrupt changes in color or grain between the splices. An “A” face will not permit sound knots, repaired knots or rough-cut veneer. An A face may allow slight mineral streak and/or vine marks. The number of defects such as pin knots or small burls varies according to the specie of veneer. This is the best face grade on plywood normally stocked and is often used for upper-end cabinetry, architectural millwork, and quality furniture.

B-Grade Face - a “B” face on hardwood plywood should be matched for a pleasing color, but not necessarily for grain. “B” grade faces are generally very similar to “A” faces, but do allow some sound or repaired knots and some slight rough cut veneer. “B” grade faces will also allow slight mineral streak and vine marks.

C-Grade Face - a “C” face on hardwood plywood allows for unlimited pin knots and small burls. A “C” face can also contain repaired knots and sound knots. The “C” grade will also allow unlimited mineral and vine marks. A “C” face should be a sound smooth face. A “C” face is used primarily on paint grade type panels, in lower-end case work, and for cabinet interiors in upper-end cabinetry.

D-Grade Face - a “D” face on hardwood plywood is similar to the “C” face, but will allow some rough cut veneer and a few more repaired and sound knots

|

| |

Q

|

| |

R

|

|

RFID

In the world of packaging and shipping, RFID offers more than just protection against theft and fraud. It helps businesses track damage, loss, error, expiration, slow delivery, and more. Shipping crates and containers are the most popular way to ship cargo around the world. RFID allows companies to track containers and shipping crates.

Read More

|

|

Rubbing Strips

The wood packaging material nailed perpendicular to the skid bottom to allow the crate to slide when handling with a forklift.

|

| |

S

|

|

Shear / Shear Strength

Is the strength of a material or component against the type of yield or structural failure where the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force.

|

|

Sheathing

Sheathing is the plywood, boards, or Oriented Strand Board (OSB) nailed to the frame members and enclose the crate.

|

|

Skids

Skids are lateral members attached to the base of the box which serve to support and transfer the load to the surface of the base.

|

|

Struts

Vertical frame members, placed between the side and end panels’ upper and lower frame members, and serve as columns for supporting vertical stacking loads. The end struts are sometimes referred to as corner posts.

|

| |

T

|

|

Treated / Fumigated

Wood packaging materials are often required to be treated with either heat or methyl bromide. Heat treatment must be conducted in accordance with a specific schedule that achieves a minimum temperature for a minimum duration of time throughout the entire profile of the wood, including its core. Various acceptable procedures exist including treatment by steam heating, kiln-drying, heat-enabled chemical pressure impregnation, and dielectric heating (microwave, radio frequency). Methyl bromide treatment requires fumigation in accordance with a schedule identifying temperature, time, and concentrations.

|

|

Top box

The top, sides and ends of the crate or box when not attached to the base.

|

| |

U

|

| |

V

|

|

Vacuum Pack / Vacuum Seal

Accomplished by placing item or assembly , with the proper amount of activated desiccant into a water-vapor proof barrier. Corrosion will not normally occur when a relative humidity of 30 percent is maintained within the barrier. Effective for a period of 18 to 24 months.

|

|

Vertical Joist Supports

Vertical members attached to the crate sides inside face, which serve to support the joists and assist the struts in supporting vertical stacking loads.

|

| |

W

|

|

Width

Is the shortest dimension of the payload when touching the ground.

|

|

Wood structural panel container

See Crate definition

|

|

Wood Packaging Material / WPM

Solid wood packaging materials, such as dunnage, crating, pallets, packing blocks, drums, cases, and skids that are used to prevent damage to cargo.

|

| |

X Y Z

|

A: A nuna flap is a piece of corrugated on the top flap that keeps the flaps open until customer cuts it out. The nuna flap helps the mills in production to keep the box straight, it gives strength when passing through the folder/gluer section.

A: A nuna flap is a piece of corrugated on the top flap that keeps the flaps open until customer cuts it out. The nuna flap helps the mills in production to keep the box straight, it gives strength when passing through the folder/gluer section.