The DIY movement has become a permanent part of just about every industry in the world. Unfortunately, just about every plan looks good on paper, so when it comes to modular designs which require physically assembling all of the pieces and ensuring that they work together safely and effectively, amateurs run the risk of dropping the ball. Simply put, there are some things that are just better left to the professionals.

Manufacturers choose to implement material handling solutions within their production lines for a variety of reasons. Many floor managers have used custom carts, racks and tables to optimize production lines with improved handling and staging. Operations managers recognize that the improved inner plant logistics can lead to better part protection and increased shop floor space.

There are typically two roads to take I) create a solution in-house using a modular building system or II) outsource the solution by calling a custom material handling manufacturer.

Modular

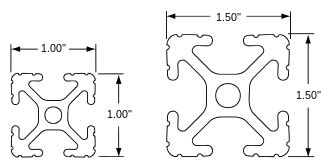

Take the modular 80/20 framing system which touts benefits such as t-slot profiles that allow the user to make adjustments and reassemble projects. This DIY system offers access to design technicians, software, sketch tools, file resources, and educational information, but this leaves most of the heavy lifting to an often inexperienced customer.

Further, the customer has to have the knowledge and savvy to interpret the plan and support tools in order to communicate with a design technician should problems arise. If the problems are complex, meaning, they are not in the design technician’s wheelhouse, the customer might be left on his own. This can be frustrating, time-consuming, and costly to the company.

Custom Material Handling Manufacturer

To put it simply, what you might get with a modular system is an inexperienced designer creating a pieced together solution. This is not the case when you work with a custom material handling manufacturer. In fact, with a custom solution, the customer will have the opportunity to work with seasoned design engineers that will approach the project from a place of authority.

Custom material handling manufacturers will assess the mechanical aspects of your assembly line and the way products are sized and handled during assembly, among other critical characteristics of your operation.

This will help them accomplish their ultimate goal—to create a solution that will fit your process perfectly. And should problems arise, the engineer will solve them for you. This means you will never be left alone to fend for yourself and rack up costly mistakes.

Working with a custom material handling manufacturer as a solution to your assembly line challenges is a collaborative effort that will lead to cost savings with a streamlined production line and more time for skilled labor to focus on the product and the company's bottom line.